Installation, Operation, and Troubleshooting Manual for

Inside

DIRECT-PLUMBED®

Containment Tanks

Models

2478SQ-NA-DP 1100Lb/150Gal Containment Tank

3072-NA-DP 1500Lb/200Gal Containment Tank

4280-NA-DP 2650Lb/353Gal Containment Tank

About this manual

Read this manual for the following information about inside Direct-Plumbed containment tanks:

• installation

• operation

• troubleshooting

Store this manual in a safe place for future reference.

About Frontline International, Inc.

• Through a dedication to the development, manufacture, and delivery of quality cooking oil management systems, Frontline

International, Inc. remains a leading global source for equipment solutions that safely and eciently dispense, contain, monitor,

extract, transport, or lter cooking oil for immediate on-premise recycling and use.

• A stakeholder focused organization, our sustainability relies on initiatives that benet associates, customers and community –

from responsible manufacturing techniques to conservation of resources and performance metrics.

• With our valued network of service and installation experts our branded and custom products enhance productivity, improve

operations and save costs for professionals within foodservice, hospitality, and other markets around the world, every day.

© 2012 Frontline International, Inc.

Specications subject to change without notice.

Direct-Plumbed is a registered trademark of Frontline International, Inc.

Table of contents

Before you begin ....................................................................................1

Read me rst ..........................................................................................1

Installation tools and materials ............................................................. 1

Installation ............................................................................................. 2

Unit placement ......................................................................................2

Outlet pipe installation .......................................................................... 2

Install ttings on top of storage tank .................................................... 2

Lowering the collection port ................................................................. 4

Plumb into ceiling ..................................................................................5

Electrical connection ..............................................................................6

Standard electrical connection ..............................................................6

Remote electrical connection ................................................................6

Connect wires to the tank ......................................................................6

Plumbing fryers to containment tank ...................................................7

Guidelines for plumbing fryers ..............................................................7

Plumbing specications ........................................................................8

Installation of the manifold assembly...................................................8

Connecting the tank to the Direct-Plumbed system .......................... 10

Direct-Plumbed operation...................................................................10

Maintenance ........................................................................................ 11

Tank cleaning ...................................................................................... 11

Heater replacement .............................................................................11

Wire diagram for control panel ..........................................................13

Warranty ..............................................................................................BC

1

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

Installation tools and materials

Read this section to see a list of installation:

• tools needed

• materials included in tank installation kit

Before you begin

Read this section for:

• important Read me rst information you should know before you begin installation

• list of installation tools and materials you need

• list of installation materials in the tank installation kit

Read me rst

Read and understand the following before beginning installation:

• To use the Direct-Plumbed system, the fryer must have built in ltration that already has or can be upgraded with a rear waster oil disposal kit.

• If a fryer does not have a built in ltration, the Direct-Plumbed system can be used by implementing a Frontline Waste Oil Pump Station.

• The installer must read and completely understanding these directions before beginning the system installation.

• Failure to understand and follow these directions may result in injuries to the installer, bystanders, and/or the equipment.

• Use caution to avoid wiring, pipes, etc. in walls when drilling holes.

• Read, understand, and follow the manufacturer’s directions for all tools and equipment being used to ensure safety.

• Use only the proper equipment for the task being performed.

• Ensure that all construction debris and dust is removed when installation is complete.

Installation tools and materials

Read this section to see a list of installation:

• tools needed

• materials included in tank installation kit

The installation tool list includes:

• Electric Drill

• 3/8” or 1/2” Pilot Bit

• 2-1/2” to 3” Hole Saw

• Hammer Drill

• 3/8” or 1/2” Masonry Pilot Bit

• 2-1/2” to 3” Masonry Core Bit

• 18” and 24” Pipe Wrench

• Hacksaw

• 9/16” Socket/Ratchet and Wrench

• Flat Blade Screwdriver or 5/16” Nut Driver

• Caulking Gun

• 50’ & 100’ Extension Cord

• 24” Level

• Permanent Marker

• 4’ or 6’ Ladder

• Paper Towels or Rags

The installation materials list includes:

• Pipe thread sealant

• Silicone caulking

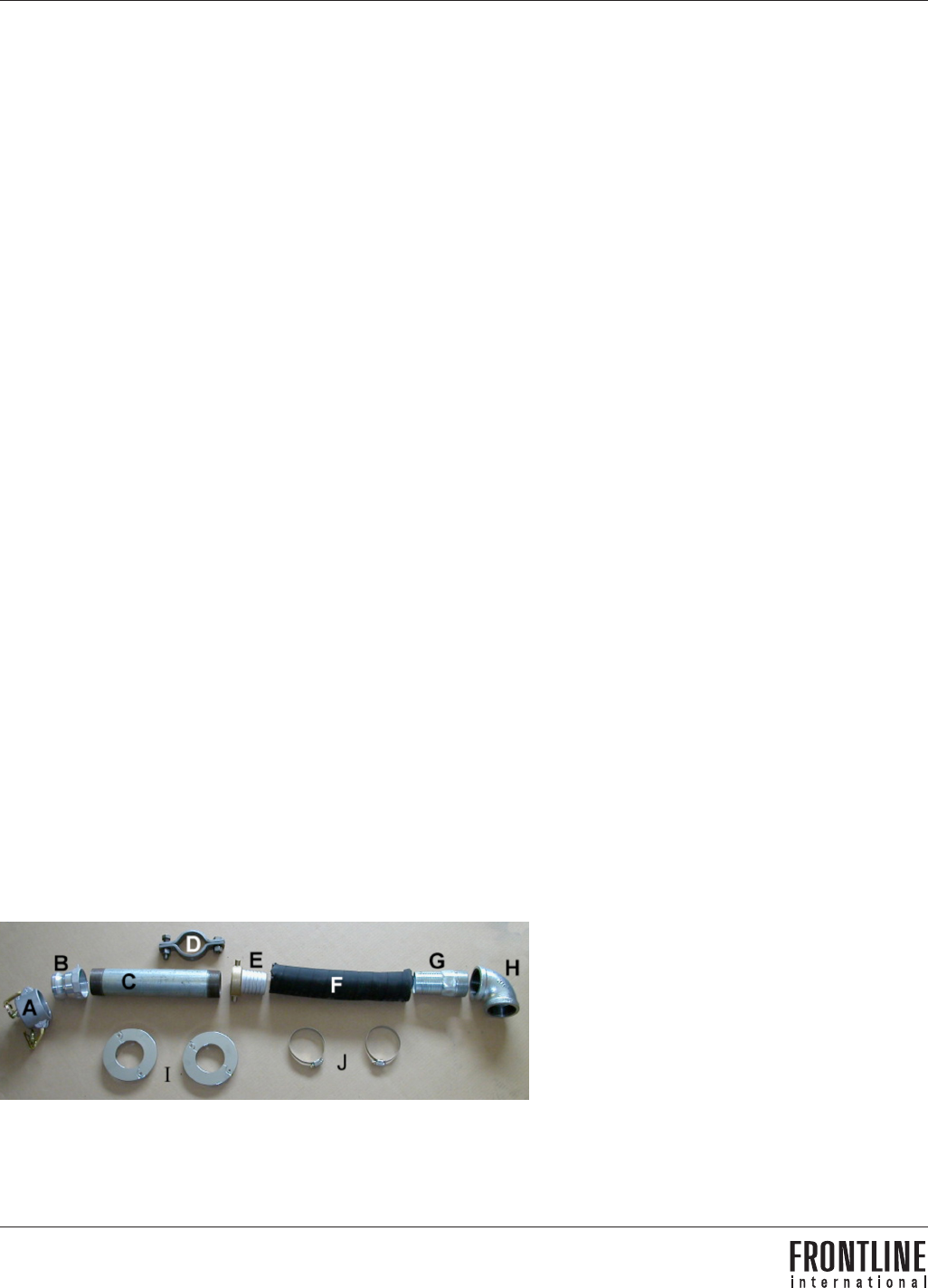

The installation materials in the Tank Installation Kit include:

Description Quantity

A. Cam Dust Cap, 2” .....................................................................1

B. Male Cam Fitting, 2” x NPT .....................................................1

C. Steel pipe nipple, 2” x 12” NPT................................................1

D. Pipe clamp ..............................................................................1

E. Barbed “Water” Fitting, 2” Barbed x 2” Female .......................1

F. Hot oil/tar hose, 2” x 12” .........................................................1

G. Barbed male adapter, 2” Barbed x 2” NPT ..............................1

H. 90º Elbow, 2” NPT ...................................................................1

I. Trim Escutcheons, 2” ...............................................................2

J. Hose Clamps, 2” ......................................................................2

2

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

!

Installation

Read this section for information about:

• unit placement

• outlet pipe installation either on top of a storage tank, by lowering the collection port, or plumbing into ceiling

• electrical connection that is either standard or remote

• plumbing fryers to the containment tank

• plumbing specications

• installation of manifold assembly

• connecting the containment talk to the Direct-Plumbed system

Unit placement

Read this section for important information about unit placement. Follow these directions concerning unit placement:

• The installer should conrm with the restaurant manager/owner the location for the storage tank.

• Keep a 31” wide by 31” deep area that is required for the installation of the storage tank.

• Exterior wall consideration - be sure the unit can be placed against an exterior wall. If not, extra piping is required to complete the

outlet installation.

• Consider the relationship of the storage tank to the fryer.

• Outside obstruction consideration - note any obstructions on the outside of the wall that will obstruct installation of the outlet pipe.

• Wall obstruction consideration - note any obstructions inside the wall that will prevent installation of the outlet pipe.

Outlet pipe installation

Read this section for information about how to install the outlet pipe either to:

• install ttings on top of the storage tank

• lower the collection port

• plumb into the ceiling

Note: Always peel the white laser lm from all stainless steel.

Note: Use thread sealant on all pipe ttings.

Install ttings on top of storage tank

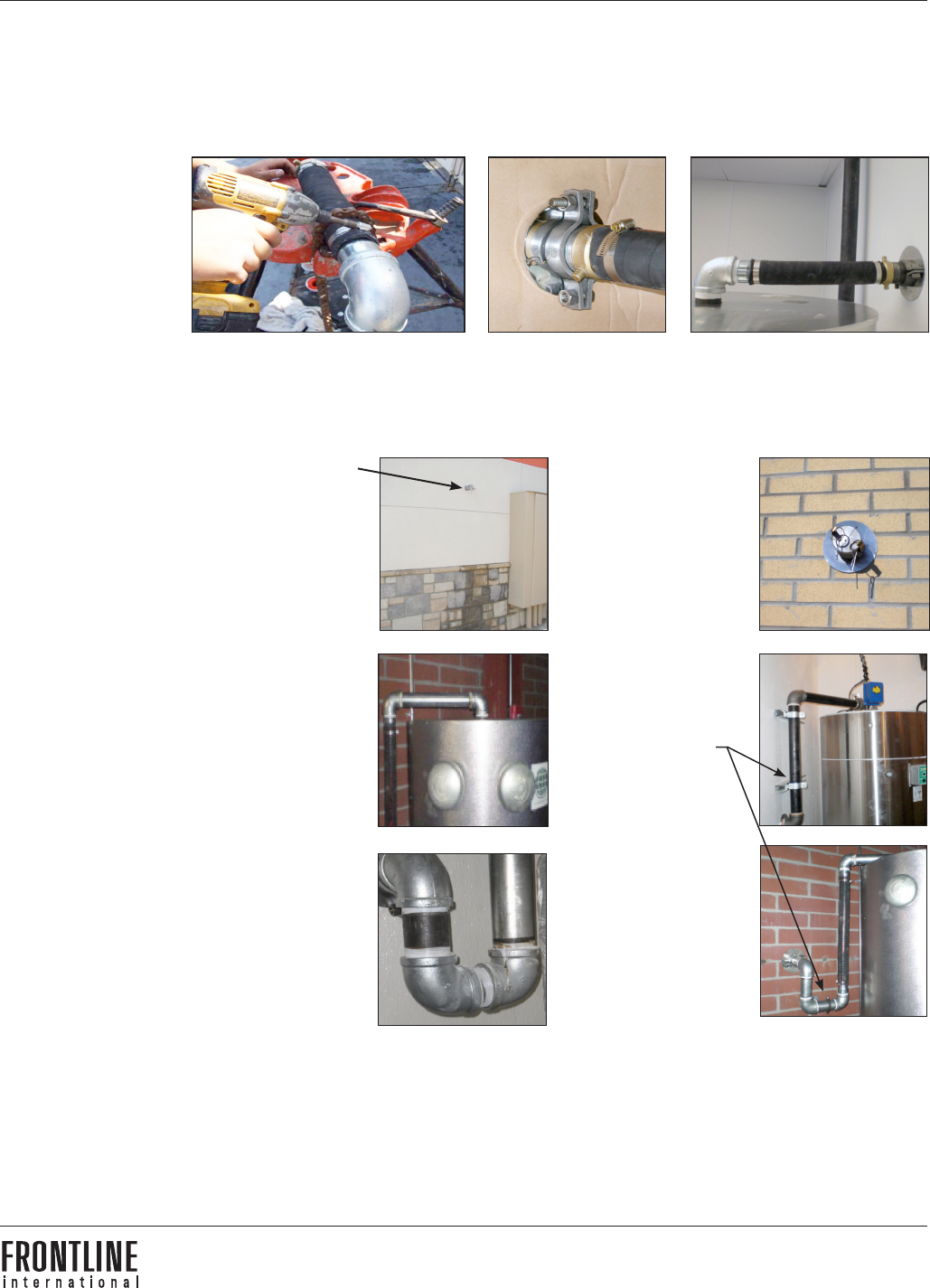

Follow these steps to install ttings on top of the storage tank.

1. Install the tting by using l the 2” 90° elbow and 2” NPT x 2” hose barb on the 2”

outlet pipe stub located in the center of the top of the storage tank.

2. Move storage tank into place. Place the storage tank into the desired location.

3. Determine location for outlet pipe through wall. Note the following:

• The installation kit will include enough materials to go from the top of the tank,

directly out the wall to the collection port.

• If the tank is not located next to an exterior wall, or the collection port needs to be

located lower, additional materials will be needed. This additional plumbing can be

mounted on the interior or exterior of the wall.

• Determine the appropriate location for the hole in the wall, and mark the location.

3

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

4. Move the storage tank out of the way, removing the storage tank from its location to allow clear access to the area.

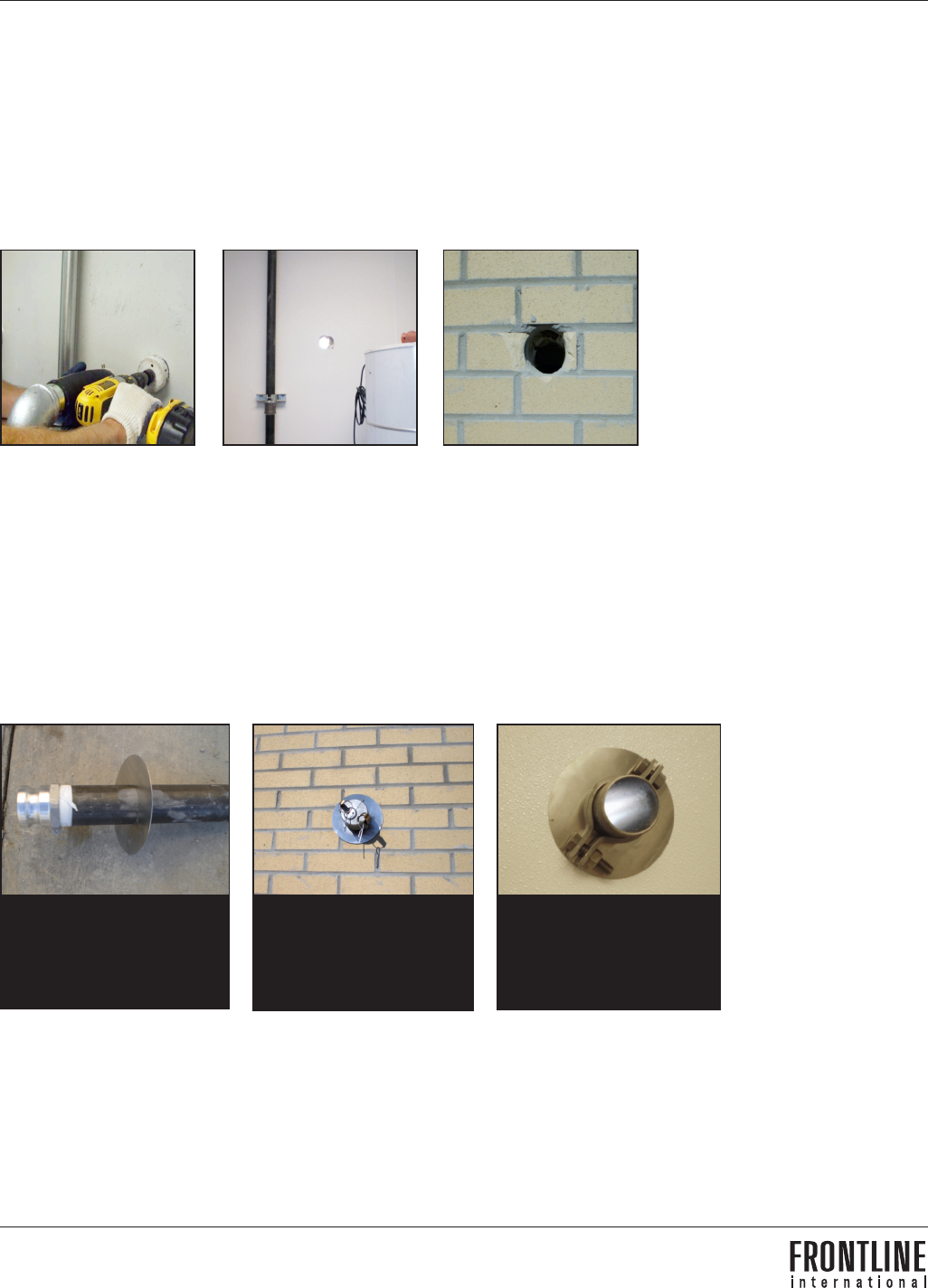

5. Drill the pilot hole, using the appropriate equipment for the type of wall construction and drilling a small pilot hole (3/8” or

1/2” diameter) all the way through the wall from the inside.

6. Drill nal hole using the pilot hole as a guide, drilling a 2 1/2” to 3” diameter hole through the wall.

• Drill the hole halfway from the inside, then complete the hole from the outside.

• Drill the hole from both sides as this will minimize damage to the wall that can be caused by drilling all the way through

from one side.

7. Remove debris, cleaning up debris and dust from drilling the hole on the inside and outside of the restaurant.

8. Install outline piping through wall, installing the pipe, ttings, and pipe clamp.

Note: Caulk around the pipe on the inside and outside of the wall to prevent water and insects from entering

the hole around the pipe. Follow these instructions:

• Assemble steel nipple with collection port and escutcheon to go through the wall.

• Place the assembly through the outside hole that was made in the wall.

• Place the other escutcheon, and clamp on the steel nipple along the interior wall and tighten.

• Keep the collection port tight against the exterior wall when tightening the clamp to keep the assembly rigid in the wall.

1. Assemble steel nipple w/collection port

and escutcheon to go through wall.

2. Place the assembly through the

outside hole that was made in the wall.

3. Place the other escutcheon, and

clamp on the steel nipple along the

interior wall and tighten. Keep the

collection port tight against the exterior

wall when tightening the clamp to keep

the assembly rigid in the wall.

9. Remove the protective laser lm covering the storage tank.

10. Move the storage tank into place.

4

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

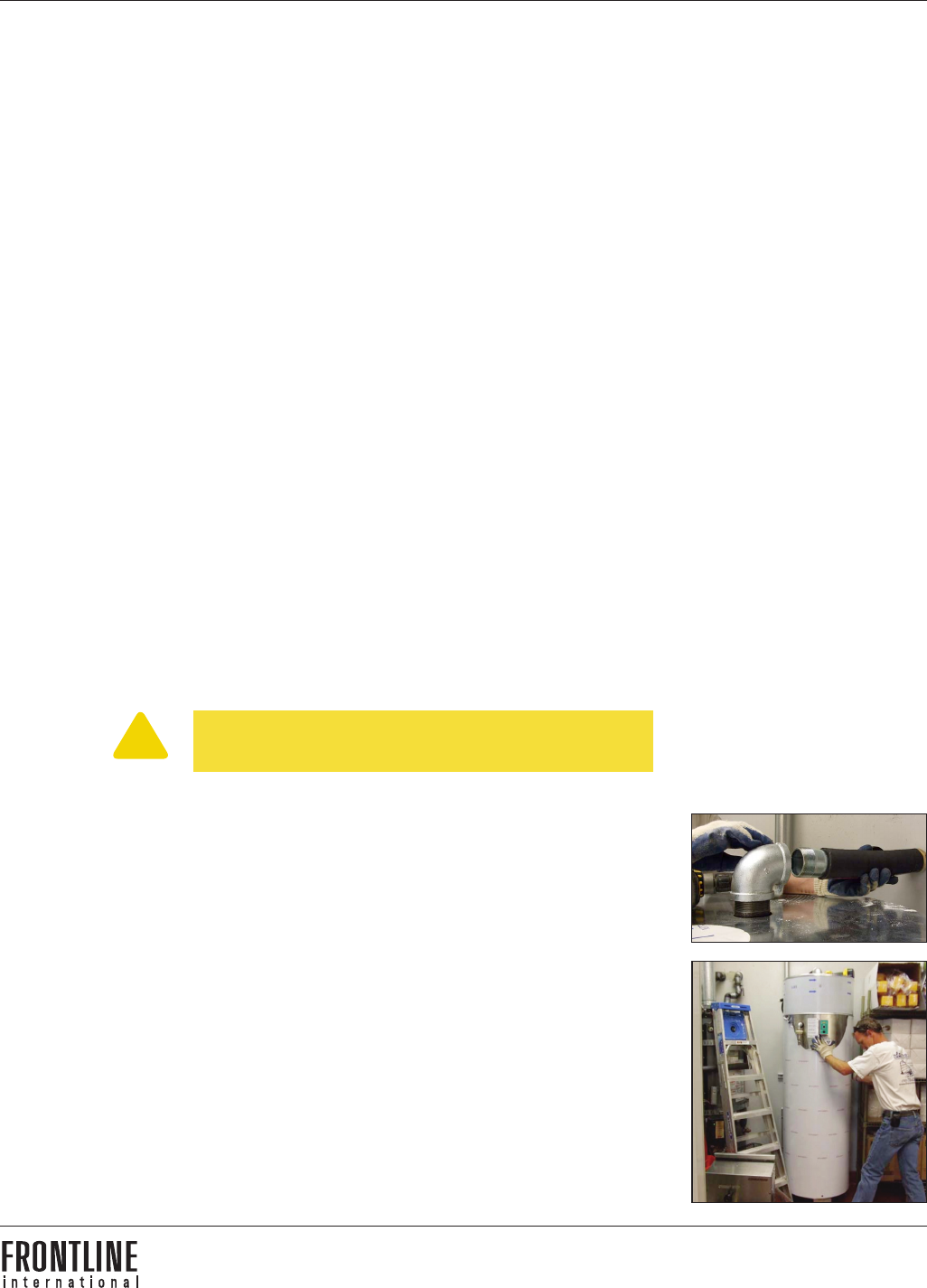

11. Measure and cut the 2” hot oil hose to the proper length and install using the 2” hose clamps. Follow these instructions:

• Place the two hose clamps onto the hose.

• Slide the barbed ends of the 2” male and female ttings into the hose.

• Tighten the hose clamps.

• Screw the male end into the 2” elbow and the gold female tting to the steel nipple.

Lowering the collection port

1. Lower the collection

port which can be done if

additional materials are used.

2 Plumb to the exterior

wall and depending on the

tank diameter and distance

the tank sits from the wall,

determine the length of pipe

needed from the 2” elbow on

top of the evacuation tube to

the wall.

3. Build a “P” trap. Using 2”

elbows, and short 2” nipples,

build a “P” trap to collect any

residual oil and to eliminate oil

spills when the cap is removed

from the building exterior.

4. Make the hole through the

exterior wall, and install the

pipe, ttings, and pipe clamp

to complete the collection port

assembly.

5. Secure the plumbing

to the wall. Using either

stand-o clamps or straps,

secure the plumbing to the

wall to support the weight of

the plumbing.

5

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

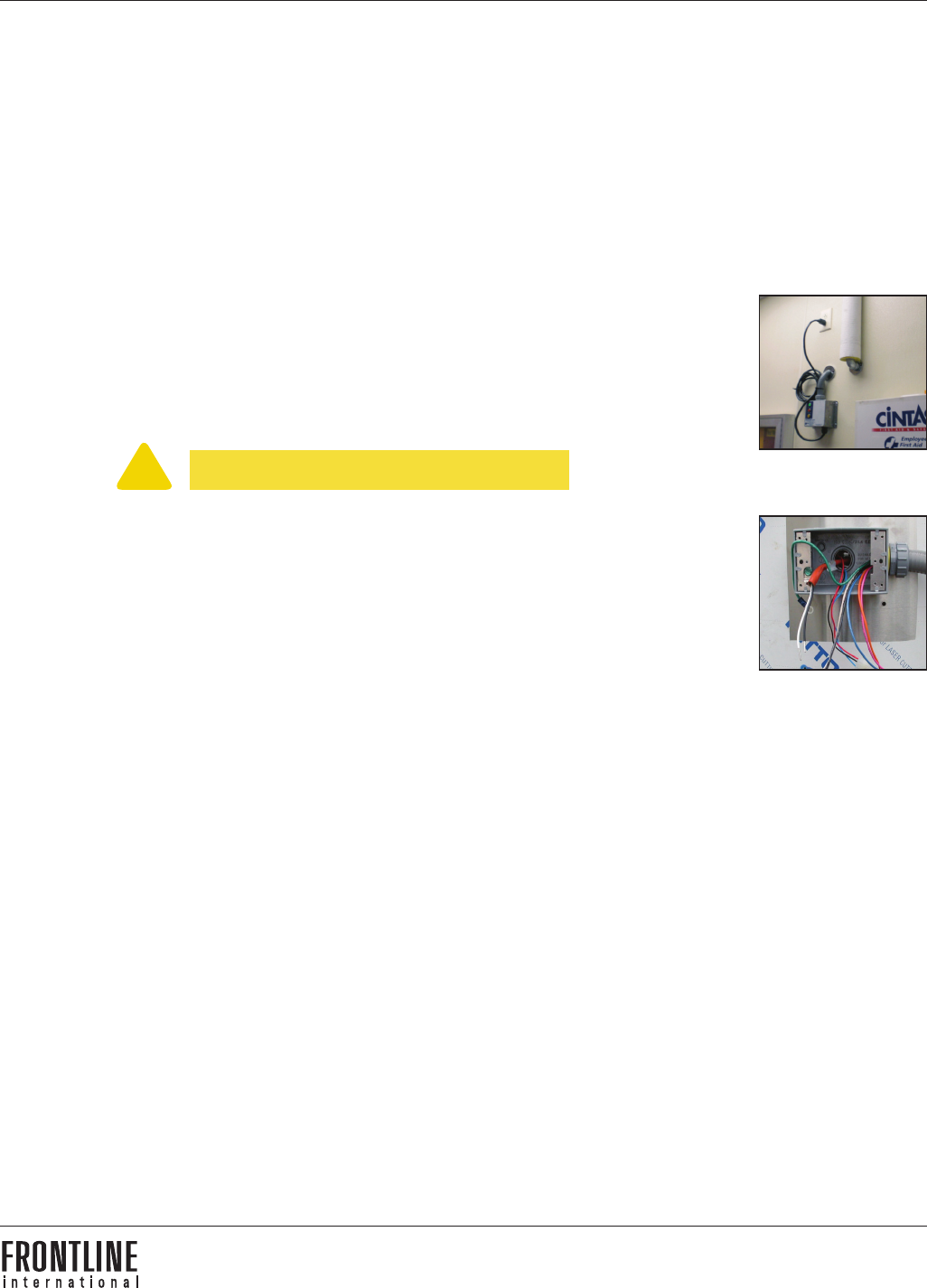

Plumb into ceiling

Follow these steps to plumb into the ceiling.

1. Attach a 2” pipe to the evacuation tube

located at the center of the tank to begin

to plumb into the ceiling.

2. Plumb to an exterior wall.

• Run the 2” line into the ceiling, and

plumb to an exterior wall using 2” pipe

or 2” hot oil hose.

• Slope this back towards the tank, so any

residual oil will drain back into the tank.

3. Plumb out of the ceiling. Bring the 2”

line down from the ceiling to the desired

collection port height.

4. Build a “P” trap, using 2” elbows, and

short 2” nipples to collect any residual oil

and to eliminate oil spills when the cap is

removed from the building exterior.

5. Make the hole through the exterior

wall, and install the pipe, ttings, and

pipe clamp to complete the collection port

assembly.

6

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

!

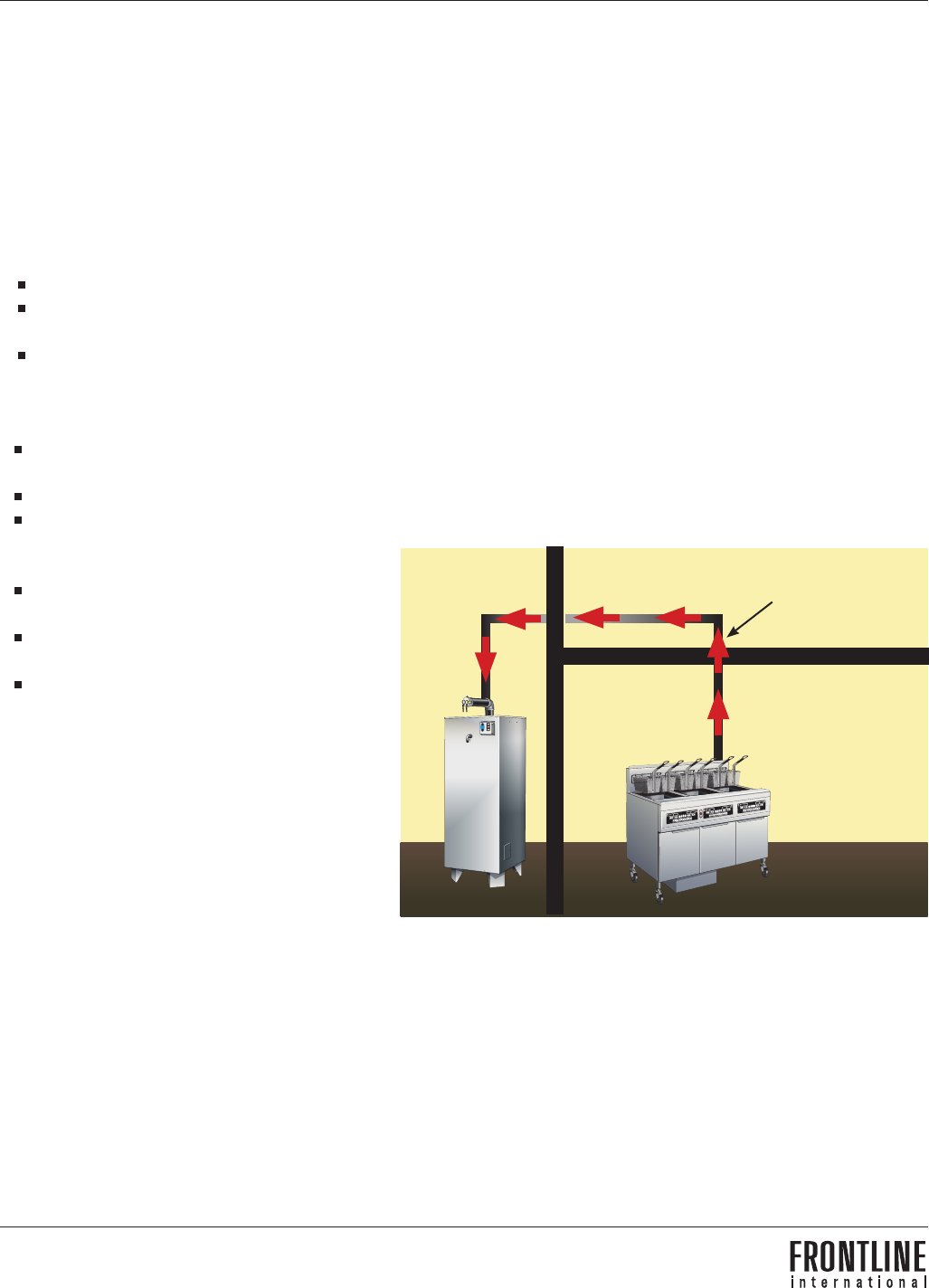

Electrical connection

Read this section for information about how to complete electrical connections as one of the following:

• standard connection

• remote connection

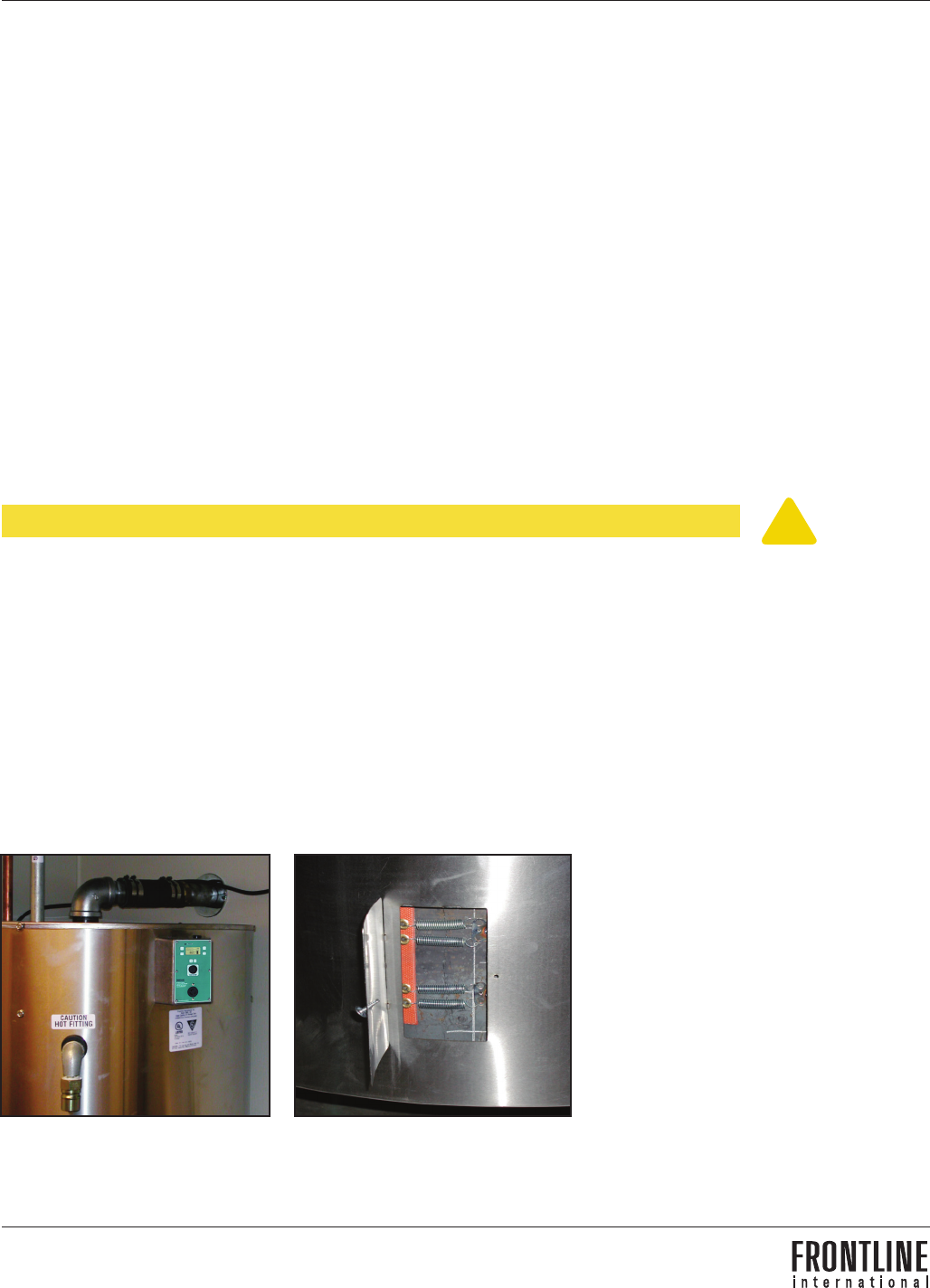

Standard electrical connection

Complete these steps to make a standard electrical connection:

1. If the control panel is mounted to the tank, plug the storage tank into a 120v 15amp outlet.

2. Be sure that the green power light comes on and remains lit. No other lights should be lit at this time.

Remote electrical connection

Complete these steps to make the remove electrical connection:

1. Note that if your control panel is to be mounted away from the tank location, it has the remote

option.

2. Mount the control panel to the wall at the desired location, making sure the control panel cord

can reach the necessary receptacle.

Note: DO NOT ENERGIZE THE SYSTEM AT THIS TIME.

Connect wires to the tank

The control panel wires connect to the junction box mounted on the tank. Follow these guidelines:

• Connect the conduit to the junction box.

• Connect the Green wires to the Green ground screw that is located in the junction box.

• Connect the heater wires (both are black) to the incoming power wires (these can be switched).

• Connect the level switch wires. These will be numbered and color coded - Orange to Orange,

Red to Red, Blue to White for Neutral.

• Connect the DP valve wires. These are numbered and color coded: Blue to Blue, Yellow to

Yellow, and Brown to Brown.

After the connections are properly made, energize the system.

7

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

Waste shortening is pumped from fryer through manifold, up, across ceiling and down to containment tank.

Plumbing fryers to containment tank

Read this section for:

• guidelines on plumbing fryers to a containment tank

• plumbing specications

Guidelines for plumbing fryers

Follow these guidelines for plumbing fryers to a containment tank:

• The Direct-Plumbed waste shortening system utilizes the lter of the fryer to pump waste shortening to the containment tank.

In practice, the shortening is dropped from the fryer vat into the lter as if preparing to lter the oil.

By means of a 3 way valve (or an additional 2 way valve) the shortening is either returned to the fry vat ltered, or it is sent to

the containment tank as waste oil.

The lter pump powers the system.

• In a typical installation where the fryer and the tank are generally on the same level, the oil is pumped out from the fryer to the

Direct-Plumbed manifold mounted on the wall behind the fryer.

From the manifold the line is plumbed (as soon as possible) vertically up to the high point of the Direct-Plumbed System

(normally above the ceiling).

From this point the ow should be down to the tank observing a minimum slope of ¼” per foot.

As a general rule, you want to have gravity do as much of the work as possible and as soon as possible.

• Using ONLY hot oil ensures that the system is self cleaning.

This operation is always performed using HOT OIL and with the

lter element in place.

The hot oil is necessary to ensure ow, and the lter element is

in place to prevent system clogging.

To assist the system in draining and to clear the system

plumbing behind the fryer, the pump is ran for an additional

20-30 seconds after the lter is empty.

Refer to the gure to see:

• The fryer is connected to the plumbing system via the Direct

Plumbed manifold mounted on the wall behind the fryer (not

shown).

• Waste shortening is pumped from fryer through manifold, up,

across ceiling, and down to containment tank.

¼” slope per foot

towards tank

Vertical rise to the high point of

the Direct-Plumbed® system

The fryer is connected to the

plumbing system via the

Direct Plumbed® manifold

mounted on the wall behind

the fryer (not shown).

8

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

!

Plumbing specications

Read the following for plumbing specications

• For Direct-Plumbed systems in kitchens using liquid shortening:

• If the plumbing is not exposed to cold weather and follows slope guidelines (¼” per foot), the plumbing does not need to

be heat traced.

• All plumbing should be ¾” schedule 40 pipe (black or galvanized) for horizontal runs = 70’.

• For horizontal runs >70’ we recommend that the horizontal run be stepped up to 1” pipe.

• The vertical rise should remain ¾” no matter what the over overall length of the plumbing run to the containment tank.

• If plumbing is exposed to cold weather, the plumbing that is exposed must be heated.

• For Direct-Plumbed systems in kitchens using solid shortening:

• Maintaining slope is crucial and all plumbing lines must be heated.

• The minimum pipe size for the horizontal run is 1” schedule 40 pipe (black or galvanized) for runs of = 80’.

• For horizontal runs of >80’, 1 ½” pipe is specied for the horizontal run.

• The manifold and vertical rise should remain ¾” no matter what the over overall length of the plumbing run to the

containment tank.

Note: Plumbing should follow as direct a route as possible and always observe slope. When plumbing is

accessible, use “T’s” with a plug rather than 90º elbows so as to facilitate the draining or cleaning of the

system.

Note: All pipe and plumbing xtures must be professionally tted utilizing high temperature pipe

thread sealant.

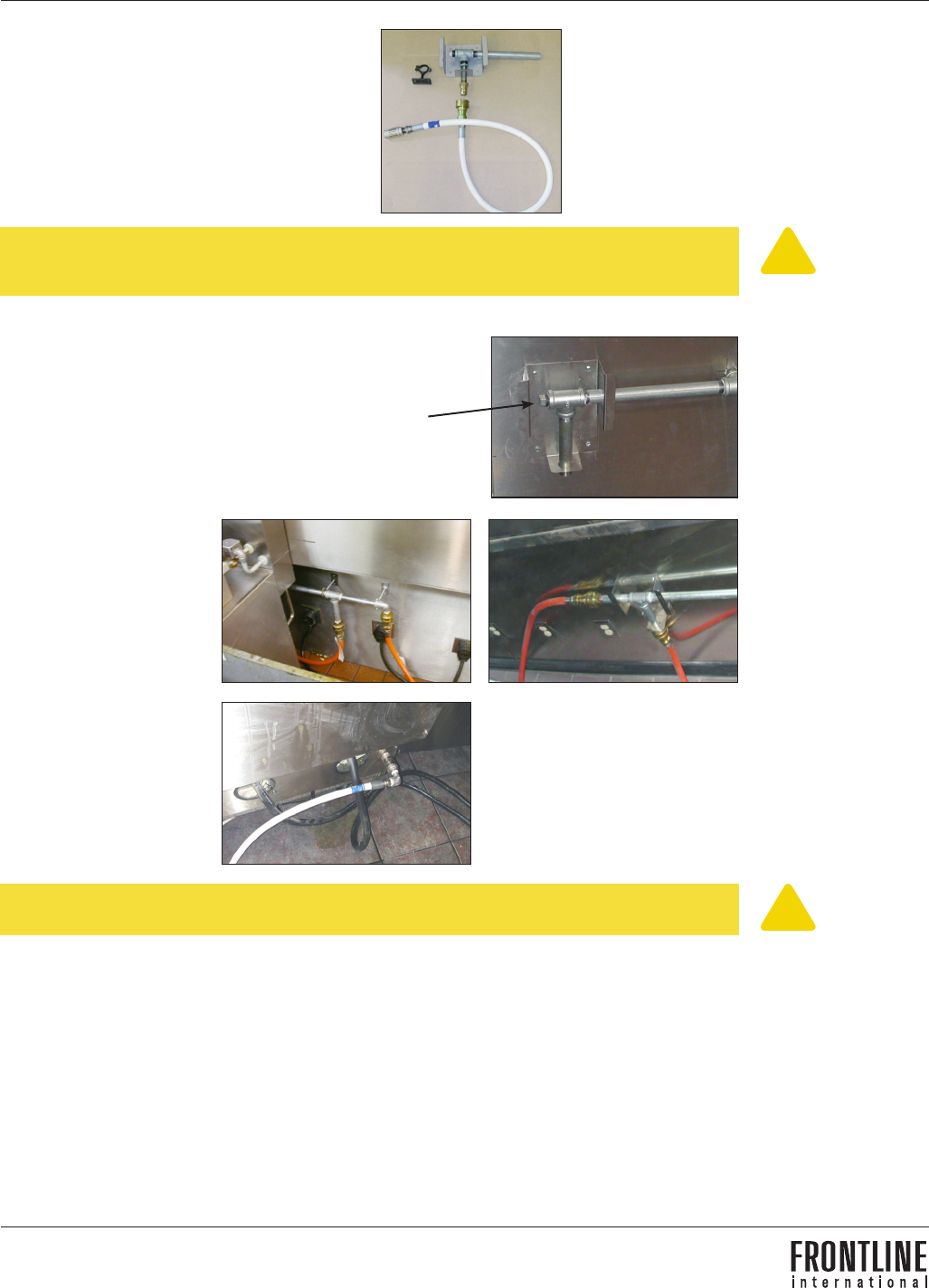

Installation of the manifold assembly

Read the following for guidelines on installation of the manifold assembly:

• Place behind the fryer, 18” to 36” above oor, and within reach of fryer connections (avoiding conict with other utilities).

• Congure the manifold components as necessary.

• Position the male quick disconnect down or to either side or both as needed and as space permits.

Note: All pipe connections must be made with ANSI/NSF 61 Thread Sealant (rated to 500 degrees and

pressure to 10,000 psi).

• When placement is nalized, pre-drill holes in stainless steel wall behind the fryer and mount the plumbing manifold with

stand os or the bracket (if provided).

• Fit and tighten all plumbing, pipe, caps and plugs using specied thread sealant.

Note: A exible high-temperature hose with a check valve (back-ow prevention) is required for the

connection of the fryer to the Direct-Plumbed manifold. If this hose assembly is not provided and already

connected to the fryer, contact Frontline International to ensure that the correct components are used for

the fryer connection.

!

!

9

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

!

!

For manifold assembly and placement, follow these instructions:

The fryer connection kit includes:

• ½ inch high temp exible hose

• ½ inch male and female quick disconnects

• ½ inch check valve

• manifold bracket

Note: Depending on the specied fryer, connection materials may be provided by the manufacturer.

Otherwise, a fryer connection kit may be purchased from Frontline international.

See the gures for single and two fryer hookups.

The gure of the single fryer hookup shows the:

• ¾” system drain plug or optional connection to the next manifold/fryer

• manifold bracket or stand os mount on the wall behind the fryer

The gures with the two fryer hookup

assembly show the manifold bracket

or stand o mounts on the wall

behind the fryer.

The gure shows the check valve

that connects to fryer waste oil outlet

Note: Ensure that the arrow on the check valve is pointing in the direction the waste oil will be owing.

10

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

!

!

!

!

¾” waste oil inlet

Connecting the tank to the Direct-Plumbed system

Follow these steps to connect plumbing to the tank.

1. With the tank installed, you are ready to connect the Direct-Plumbed plumbing to

the waste shortening containment tank waste oil inlet. The tank leaves the factory

with a ¾” ball valve installed and wired at the top of the tank.

2. Using the specied high temperature pipe sealant on the male threads for all

plumbing connections, you can make the nal connection between the tank and

the horizontal plumbing run back to the tank position.

3. To give installation exibility a ¾” x 12” stainless steel braided Teon hose is

included with the Direct-Plumbed installation kit. This exible hose can be used

at any point in the plumbing to assist with the connection of the tank to the DP

System plumbing (use caution not to twist or kink the ex hose).

4. Use the recommended ¾” “T” and plug arrangement in the exposed plumbing line

when connecting the tank to facilitate the draining of the Direct-Plumbed system

for system maintenance purposes.

¾” electronic

actuated ball valve

Direct-Plumbed operation

Read this section for information about Direct-Plumbed operation. Follow these steps concerning operation.

1. Make sure the containment tank control panel is plugged into a live 100v 15amp circuit

and the green power light is lit at all times.

Note: If power is lost, the tank could overow.

2. When wasting oil to the tank, be sure the tank is not full.

Note: Wasting oil when the tank is full may result in equipment damage.

3. Depending on the fryer model, you need to turn the appropriate hand to redirect the oil

to the waste oil storage tank.

Note: Your fryer pump may engage when the discharge handle is moved, or your fryer may have a separate ON/

OFF switch that you need to turn on.

4. Perform disposal of waste shortening from the fryer using hot oil and with the lter element in place. Hot oil is necessary to

ensure ow, and the lter element is in place to prevent system clogging.

5. To assist the system in draining and clear the system plumbing behind the fryer, run the pump an additional 20-30 seconds after

the lter is empty.

Note: As long as only hot shortening is wasted, the Direct-Plumbed system is self- cleaning.

DP Control Panel

11

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

Maintenance

Read this section for instructions on:

• tank cleaning

• heater replacement

Tank cleaning

With proper care, the completely stainless steel encased storage tank will maintain a great nish for years. Follow these guidelines to

clean the tank if needed:

• As grease and other dirt come into contact with the tank surface, use a warm mild detergent to clean all surfaces.

• Occasional cleaning with a commercial stainless steel cleaner/polisher is recommended.

• As the nish of the tank is a brushed nish, never use any abrasive materials (steel wool, pan scrubbing pads, etc.) as this

will scratch and dull the surface.

Heater replacement

Proper use of the equipment should provide many carefree years of use for most major system components. Should repair or general

servicing be required, use the following steps to change out the heater component in 10-15 minutes. If you have questions, call

Frontline International Inc. at 330-861-1100.

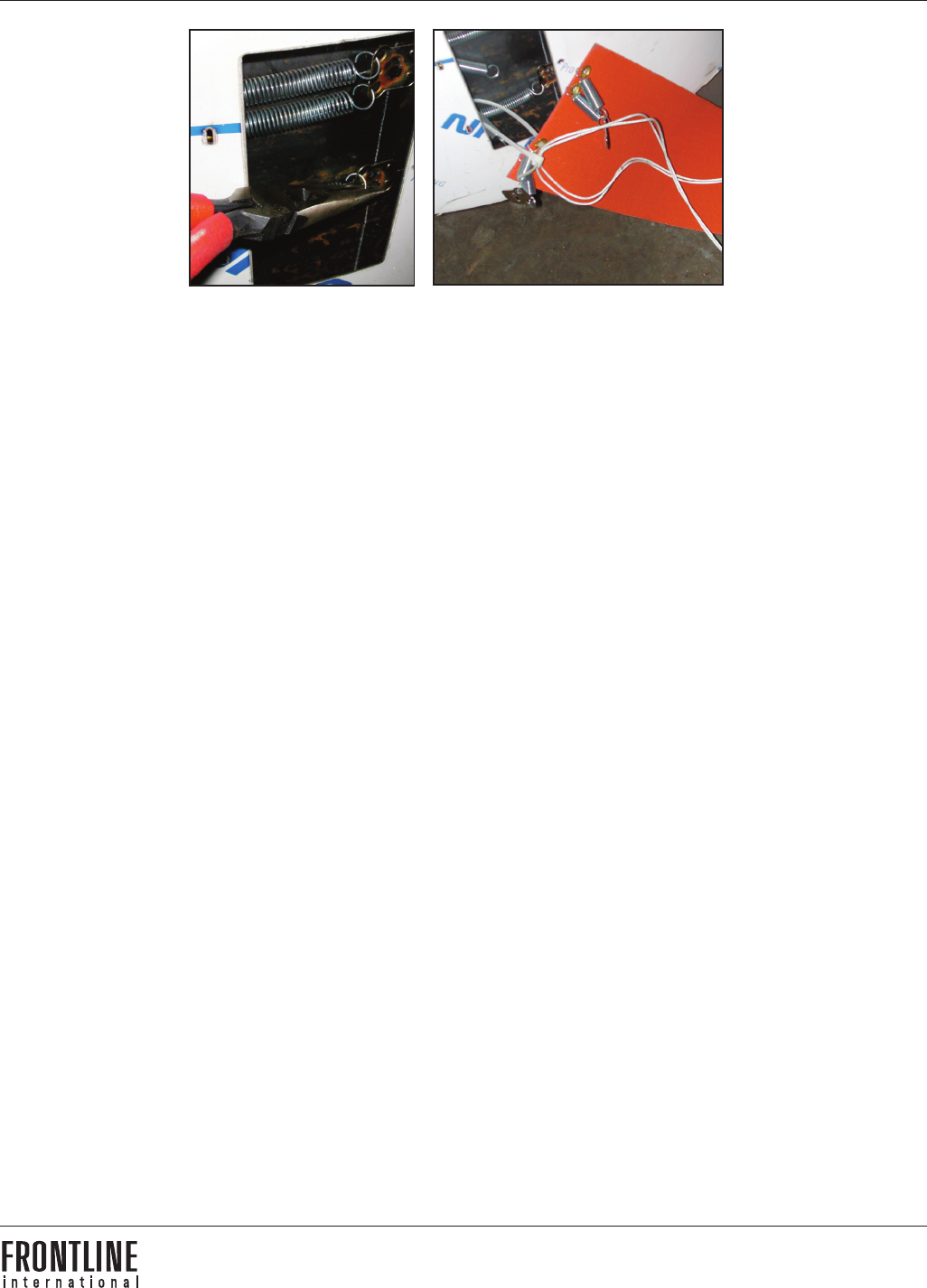

WARNING - TURN OFF THE BREAKER AND UNPLUG THE UNIT TO PREVENT ELECTRICAL SHOCK.

1. To change out the heater, be sure you have access to both heater access doors. If the installation location of the tank does not allow

access to both doors:

• The tank must be disconnected from the wall and moved.

• If tank is direct plumbed to the fryers, the ¾” steel ll pipe must be disconnected before moving tank.

2. Find the two heater access doors on the lower portion of the tank.

3. Using a #2 Phillips screwdriver, remove each retaining screw from each door (1 each) and take cover completely o.

4. On the right side access door opening, pull out and cut the excess wire and tape them to the outer skin of the tank to assure they do

not get lost.

!

12

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

5. Using needle-nose pliers, remove the 4 springs from the weld-tabs on the tank to free the heater. Note that this must be

performed at each end to allow heater removal.

6. Attach the new heater to the old heater and pull the old heater outward on the right side opening.

7. Using wire nuts or butt connectors, splice the two wires and assure the connections are secure by pulling on each lead indepen-

dently.

8. Slide new heater the rest of the way in and secure the 4 springs on each end to the retaining clips welded on the tank. Note that

the springs will require tension to assure proper pressure of the heater against the tank.

9. Plug the tank back in and check to make sure the heater heats up

13

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

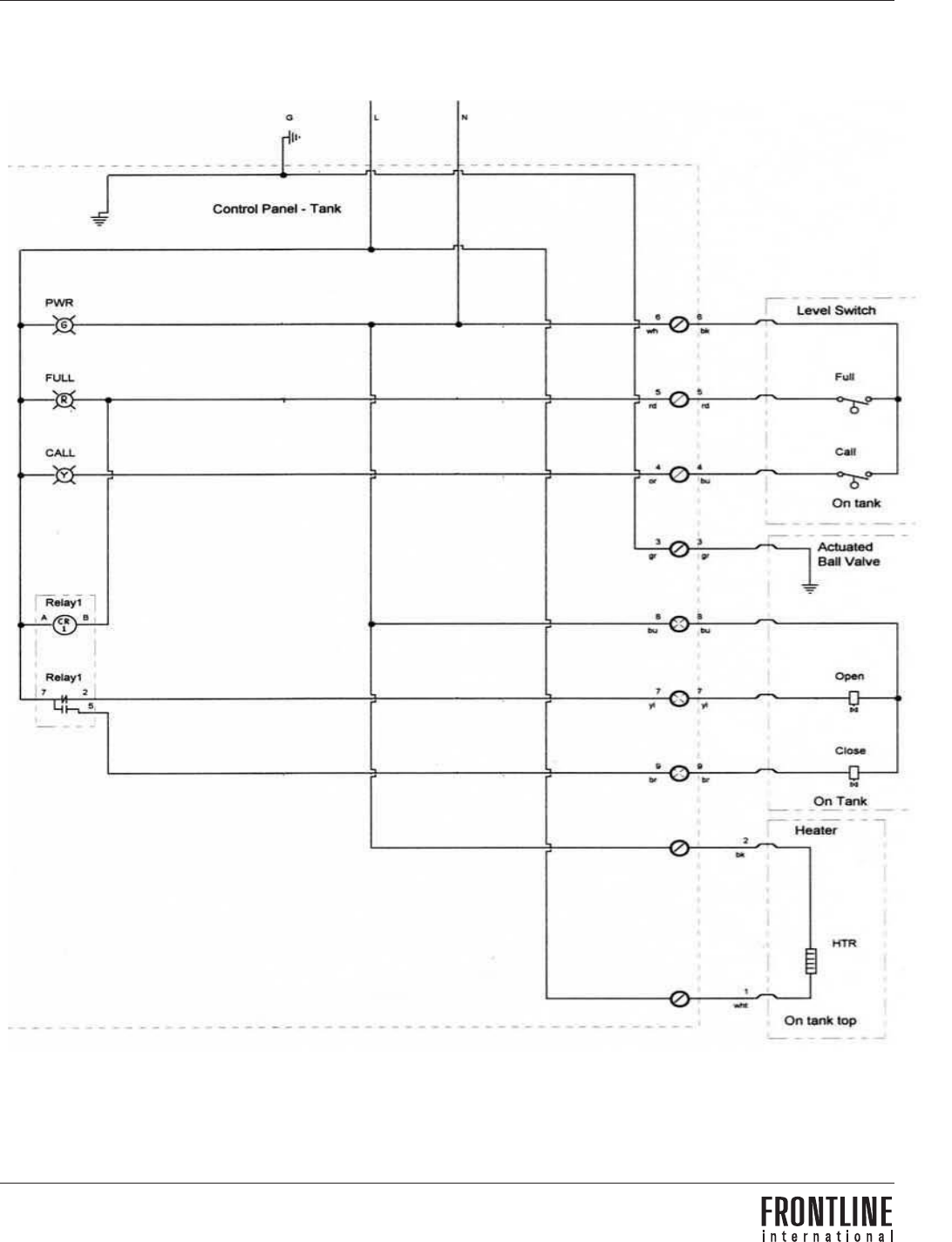

Wire diagram for control panel

Tank Control Panel

Frontline International Inc.

Frontline International Inc. ● 95 16

th

Street SW ● Barberton, OH 44203 ● Phone: 330-861-1100 ● Fax: 330-861-1105

Tank Control Panel Model 70020012

Wire Diagram

14

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks

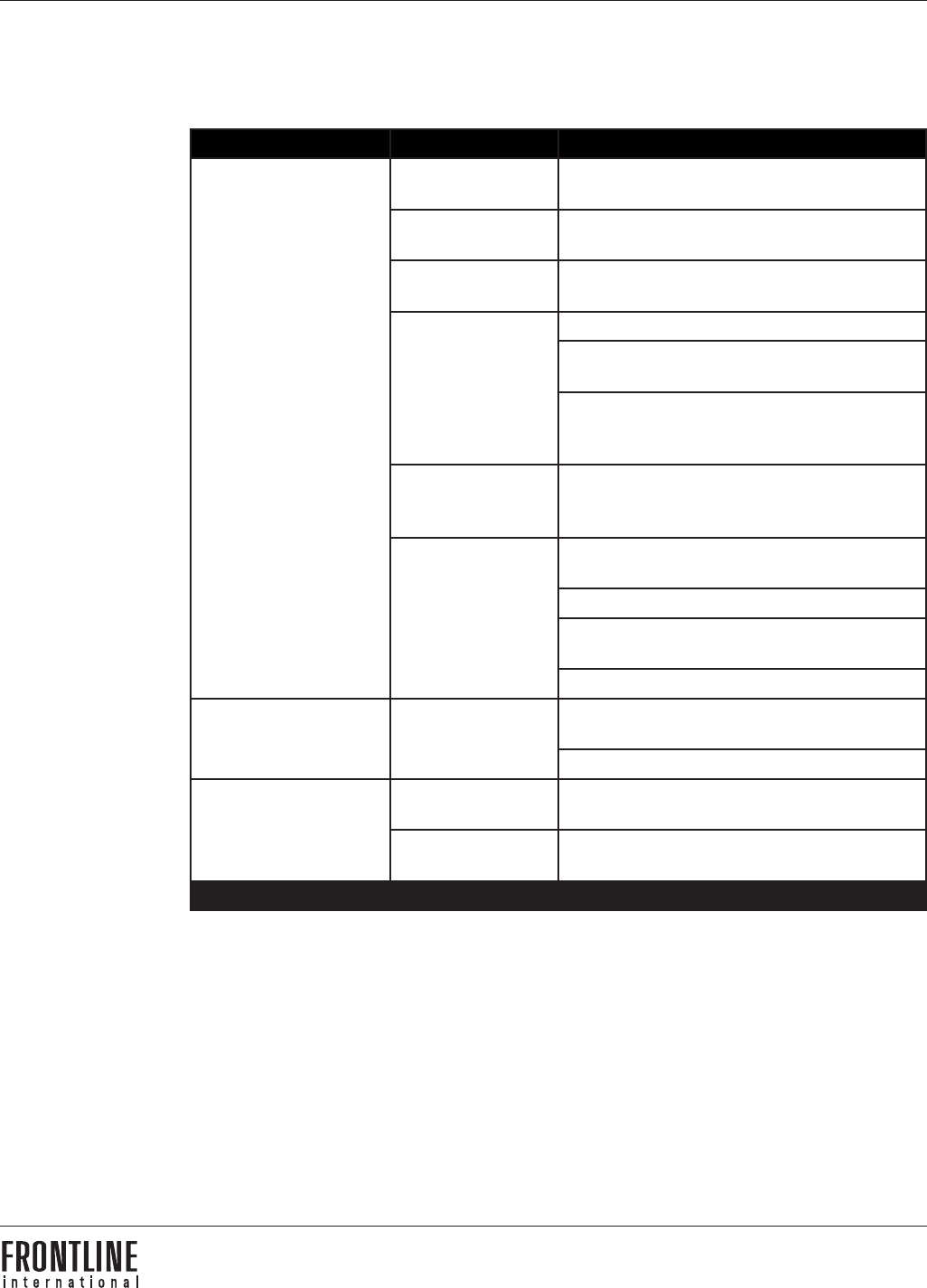

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Oil won’t pump from lter

The fryer motor is not

turning on.

Ensure the fryer motor is plugged into the power source.

Fryer motor reset switch

has tripped.

Press the motor reset switch on the back of the fryer motor.

The lter element is

clogged.

Replace the lter element.

The tank or control panel

has lost power.

Ensure the tank or control panel are plugged in.

Ensure the outlet that the tank or control panel is plugged into

has not lost power.

If there is no power to the outlet, make sure the circuit breaker

has not tripped or that the outlet is not on a switch that has

been turned o.

The exible hose behind

the fryer is not connected.

Make sure the female disconnect tting is properly connected

to the male tting.

Fryer hose or plumbing

may be plugged with

grease.

Remove the fryer hose and run it under hot water to liquefy any

grease that may be clogging the hose.

Remove any plugs from tees to check for any clogged lines.

Make sure that nothing is blocking the inlet tube that goes

down into the oil.

Assure that the oil being discarded is in liquid state.

Rendering company is unable

to empty grease from

containment tank.

Heater belt has lost power.

Assure the tank is plugged into a power outlet, and the circuit

breaker has not been tripped.

The heater belt has gone bad and will need replaced.

Tank is overowing.

System has lost power.

Ensure the tank is plugged in and the wall receptacle has not

lost power.

Mechanical oat needs

cleaned.

Remove the oat from the top of the tank, and clean with

degreaser.

Call 330-861-1100 if you have checked all of the above and the problem still has not been resolved.

Troubleshooting

See the following table to troubleshoot problems

15

Inside Direct-Plumbed® Containment Tanks | Frontline International Inc.

Warranty

Limited Warranty for Frontline International, Inc. Appliances

Subject to the following conditions, Frontline International Inc. makes the following limited warranties to the original

purchaser only for Frontline International appliances and replacement parts:

NEW EQUIPMENT: Any non-user part of a new appliance, except lamps, which proves to be defective in material or

workmanship within one (1) year from date of original shipment, will be repaired or replaced without charge F.O.B. factory,

Cuyahoga Falls, Ohio, or F.O.B. authorized distributor. Non-user parts on systems specically include heater, level switch,

and the control panel. Motors, pumps, and customer abuse will not be covered by this warranty.

REPLACEMENT PARTS: Any appliance part, except lamps, which proves to be defective in material or workmanship

within ninety (90) days from the date of original installation, will be repaired or replaced without charge F.O.B. factory,

Barberton, Ohio or F.O.B. authorized distributor.

This warranty for new equipment parts covers the repair or replacement of the defective part, and any labor charges for the

removal and installation of any non-user part specied above. Replacement parts do not have any labor coverage.

Any claim must be represented to either Frontline International or the distributor from whom the appliance was purchased.

No allowance will be granted for repairs made by anyone else without Frontline International’s written consent. If damage

occurs during shipping, notify the sender at once so that a claim can be led.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST FRONTLINE INTERNATIONAL FOR ANY BREACH

OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) to cold oil

in storage tank due to main power being removed or unplugged from a system; (c) if the equipments serial number is

removed or defaced; or (d) for lamps.

THE ABOVE LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. FRONTLINE INTERNATIONAL NEITHER

ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

16

Frontline International Inc. | Inside Direct-Plumbed® Containment Tanks